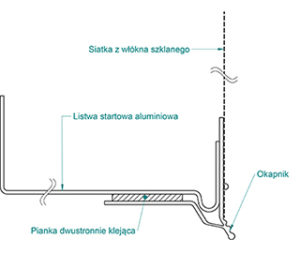

Application: for making the starting tray in the assembly of thermal insulation cladding

Assembly: ALU BP30 starter strips are available in five dimensions of the tray width adapted to the thickness of the thermal insulation cladding: styrofoam or wool: 100mm, 120mm, 150mm, 180mm, 200mm. The strips are manufactured in three thicknesses of aluminium sheet: 0.5mm, 0.6mm and 0.8mm. The name of the ALU starter strip, e.g. BP30 L200 W150 0.8mm, means that this is a strip with a length of 2 meters, 15cm wide and sheet thickness of 0.8mm. Assembly of the strip is done by permanently fixing the strip to the building wall using expansion bolts. The strip should be levelled. Further assembly involves inserting the thermal cladding into the starter strip’s tray. At the base, ALU starter strips are profiled so that a bottom edge has a drip, which prevents the water from leaking under the protruding edge of the thermal cladding.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

It is recommended to use the BP14 LUX COK dripnose bead for the aluminium starter strips. The BP14 LUX COK bead should be glued down from the bottom to the aluminium starter strip using a special foam adhesive tape that is included on the BP14 LUX COK bead. Then, glue the fibreglass mesh mounted on the BP14 LUX COK bead to the surface of the thermal cladding with glue for embedding the fibreglass mesh into the insulated render, overlapping the mesh by 10cm with the façade fibreglass mesh and draw both meshes with adhesive. The BP14 LUX COK bead provides a very aesthetic, even finish of the lower part of the façade in the form of a solid PVC dripnose bead and, above all, eliminates frequent plaster breaking at the edge of the aluminium starter strip and structural plaster.

| ||||||||||||||